|

Hebei Jinli Casting Inc.

|

Compacted Graphite cast iron

| Place of Origin: | Shanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

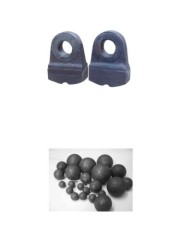

Compacted Graphite cast iron, Compacted Graphite iron, CGI IRON,CGI CAST IRON,CGI casting, Vermicular Graphite Iron

Compacted Graphite Iron is also known as CGI iron and Vermicular Graphite Iron. This material was developed around the same time as SG Iron – Ductile Cast Iron back in the 1940's but it is only recently that designers and engineers have started to full utilize its unique mechanical qualities. In simplistic terms CGI is neither a Grey Iron nor a SG Iron; it falls in to a category that is somewhere in-between.

The graphite formation in Grey Iron is in the form of a flake; SG Iron exhibits graphite in the form of spheres. Compacted Graphite has blunt flakes that are interconnected thus offering the beneficial properties of Grey Iron and SG Iron. Compacted Graphite Iron Castings has a greater tensile strength than Grey Cast Iron. Compacted Graphite is almost twice as strong as Grey Cast Iron but it retains the ability to be produced cast near to shape, and has low manufacturing costs.

Compacted Graphite Iron is also known as CGI iron and Vermicular Graphite Iron. This material was developed around the same time as SG Iron – Ductile Cast Iron back in the 1940's but it is only recently that designers and engineers have started to full utilize its unique mechanical qualities. In simplistic terms CGI is neither a Grey Iron nor a SG Iron; it falls in to a category that is somewhere in-between.

The graphite formation in Grey Iron is in the form of a flake; SG Iron exhibits graphite in the form of spheres. Compacted Graphite has blunt flakes that are interconnected thus offering the beneficial properties of Grey Iron and SG Iron. Compacted Graphite Iron Castings has a greater tensile strength than Grey Cast Iron. Compacted Graphite is almost twice as strong as Grey Cast Iron but it retains the ability to be produced cast near to shape, and has low manufacturing costs.

Good fatigue properties, ease of machining, good thermal and damping properties make this an ideal choice for applications such as engine blocks, flywheels, clutch components, piston rings, turbo housings, exhaust manifolds and brake drum.

Various national and international organizations have developed and published standards for Compacted Graphite Iron. These standards specify the CGI grades in terms of the tensile strength and the graphite microstructure, expressed as Percent Modularity. The currently available standards are summarized as follows:

Summary of CGI Standards

Good fatigue properties, ease of machining, good thermal and damping properties make this an ideal choice for applications such as engine blocks, flywheels, clutch components, piston rings, turbo housings, exhaust manifolds and brake drum.

Various national and international organizations have developed and published standards for Compacted Graphite Iron. These standards specify the CGI grades in terms of the tensile strength and the graphite microstructure, expressed as Percent Modularity.