|

Hebei Jinli Casting Inc.

|

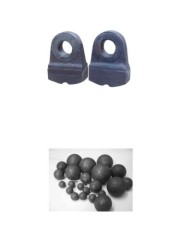

Ni resist cast iron

| Place of Origin: | Shanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Ni-Resist, Ni resist cast iron or Ni resist castings is one main type of our alloy cast iron parts, which is mainly used in Gas Turbines and automoti

Ni-Resist, Ni resist cast iron or Ni resist castings is one main type of our alloy cast iron parts, which is mainly used in Gas Turbines and automotive exhaust and turbocharger systems, where temperature fluctuates between 500 and 1050 centigrade. Ni-resist is suitable in these applications because its ductility, hot strength and low coefficient of thermal expansion.

There are two families of Ni-Resist austenitic cast irons. These are the standard or flake graphite alloys and the ductile or spheroid graphite alloys. As time passes, the spheroidal grades, because of higher strength, ductility and elevated temperature properties are becoming more prominent. However, the flake materials with lower cost, fewer foundry problems and better mach inability and thermal conductivity are still produced by many cast iron foundries. The main Ni-resist parts include: oil-submersible pump parts, oil pump housing and oil pump impeller; internal combustion engine parts; engine exhaust manifold, turbine housing, turbocharger casting. General characteristics of both groups are described bellow.